Study Of Dewatering machine

In

knit fabric finishing process; de-watering machine is used in case

of tube or open form fabric after dyeing. In case of piece goods fabric hydro-extractor machine is used for water removing. During

de-watering process additional chemical is used for soften the fabric.

Different types of operational parameter are controlled during de-watering

process.

Main Feature:

Ø The

dewatering machine is made of high quality stainless steel.

Ø Superior

performance, smooth running.

Ø High

dewatering rate.

Ø Made by

Germany technology according to international standard

Ø It has the

characteristics of high capacity, low consumption.

Ø A system of

shock proof, timing, automatic and safety control.

|

| Study Of Dewatering machine | Textile Dyeing Machineries |

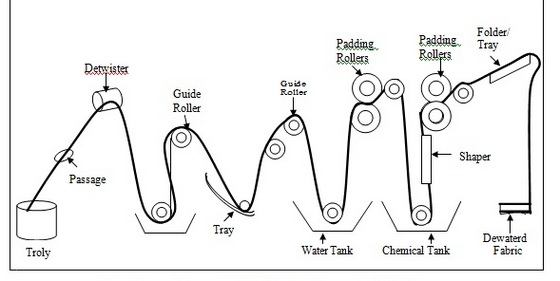

Dewatering Machine Parts and Their Functions:

De-watering machine

has different parts and every single part has specific functions.

Followings are de-watering machine parts name with their functions. - Hand Wheel: It is a manual process. It is used for guide the spreader.

- Turn Tube: Fabric rotation is controlled by turn tube. It also helps in fabric feeding to the spreader.

- Squeezing Roller: It is the main part of the de-watering machine. Water of the wet fabric is squeezed by the squeezing roller.

|

|

Figure: Dewatering

dyeing machine.

|

- Guide Wheel: Guide wheel helps to feed the fabric into the squeezing roller.

- Spreader: When fabric is dye in a dyeing machine it found in rope form. After dyeing, when dyed fabric is put in basket it also remains in rope position. By spreader we can open fabric from the rope position. It can be spread and compressed in width direction by its hydraulic cylinder.

- Security Shield: Security shield is an emergency switch settled with a plastic board very near to the padder. When it is close to the padder it is on and when it is pulled back then it is off. In case a big knot is going to pass the padder then it immediately pulls back the board to stop the machine. It is an automatic system to ensure the security of the padder. It helps to avoid any types of incidence.

- Air Injection Switch: It pushes air into fabric to turn it to ballooning form. It helps to turn the rope form fabric into open form.

- Photocell: Photocell is an auto sensor which control air injection.

Another Important Features of Dewatering Machine:

- Single squeeze roller and single padder present.

- One for squeezing and other for applying softener finished.

- Above 80% water can be removed

- Maximum 60 inch diameter can be extended.

- Softener tank present.

De-Watering machine plays an important role in knit finishing section of the knit fabrics. De-watering machine is used for reducing water from the wet fabric. It reduces the water content of the fabric.

Related tag:

What is the working principle of dewatering machine?

What is the concept of dyeing machine?

What is the working principle of winch dyeing machine?

What are the elements of a dyeing machine?

dewatering machine price in bangladesh

santex dewatering machine

function of dewatering machine

hydro extractor machine in textile

slitting machine in textile

slitter machine working principle

function of hydro extractor machine

slitting machine Wikipedia