Study Of Slitter machine

Slitter

machine is used for tubular knit fabric to make it in open form. In open form

fabric finishing line; slitter machine is used after hydro-extractor,

de-watering and drying machine.

Slitting is a process that is applied for cutting the tubular fabric through the intended break Wales line on lengthwise direction prior to stenter processing. During slitting, it is required to be aware about the cutting line otherwise, fabric faults can be occurred there.

Slitting is a process that is applied for cutting the tubular fabric through the intended break Wales line on lengthwise direction prior to stenter processing. During slitting, it is required to be aware about the cutting line otherwise, fabric faults can be occurred there.

|

| Study Of Slitting machine |

Function of the Slitting Machine:

- Used to remove excess water after pretreatment and dyeing

- To slit the tube fabric by the knife for opening of the fabric and ready for stentering;

- Delivered fabric increase Free State

- Before squeezing balloon is formed with the help of compressed air passing by a nozzle or air sprayer;

- It can control the diameter of fabric and GSM and shrinkage by over feeding mechanism.

Objectives of Slitting:

- Following objectives are achieved by the slitting machine.

- To open tube fabric according to specific needle mark;

- To prepare the fabric for next stuttering.

|

| Study Of Slitter machine | Textile Dyeing Machineries |

Main Parts of Slitter Machine and their Functions:

Following are the main machine parts and their functions.- Rotary Blade: Rotary blade is used for cutting the fabric through break Wales line.

- Ring: Ring is use to help the cutting process.

- Guide Roller: After slitting, plaiting of the fabric is done. Guide roller guides the fabric to plaiting.

- Plaiting: Open fabric is make plait by plaiting.

- Sensor: Sensor is used for identify the specific Wales line. It makes sense for cutting through break Wales’s line.

Working Principle of Slitter Machine:

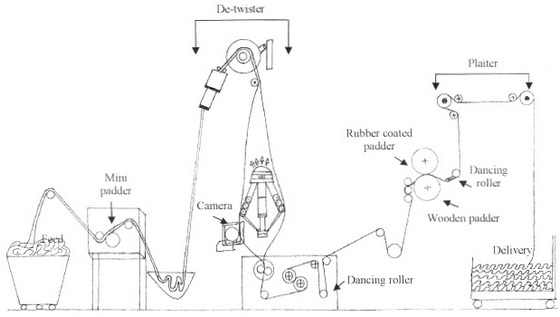

The slitting m/c has 4 units - initial squeezer, de-twisting, slitter and padder. After dyeing completed and falling of water from fabric the fabric is fed in slitting m/c. So it is necessary to remove some water initially for the case of further processing in this m/c.

The initial squeezer does this work. The de-twisting unit removes twists that may present in tubular rope form fabric. This unit has 3 de-twisting rollers, one rotation drum and 2 feeler rollers with sensors. By these rollers it detects twist in fabric and removes by rotating rope fabric in opposite direction.

Before slitting there is a blower which blows air to open the tubular fabric & makes it easy to pass over cigger. The cigger can be extended in circumference and opens the tubular fabric in full circumference. Slitting is done by using open mark detecting golden eye by around knife. Then the fabric passes through the padder where washing or chemical treatment is done.

Squeezer is used to remove 60-70% of water. After removing water width is controlled by stretcher and fabric is delivered by folding device.

| |||||

| Line diagram of slitting machine |

Checking Parameters Slitter:

Following parameters are checked after slitting.

- Cutting Line Check: Fabric cutting line is checked by the operator of the slitting machine. Operator checks that the rotary blade cut fabric through break Wales’s line or not.

- Bow and Slant check: Bow and slant is checked in the delivery side of the machine by the operator.

- Fabric Faults: Various fabric faults also checked in slitting process.

Related tag:

What is the purpose of slitter machine?

What is slitter process?

What are the parts of a slitter?

types of slitting machine

slitting machine process

slitting machine function

textile slitting machine

bianco slitting machine

bianco slitting machine origin

slitting machine price