Winch dyeing machine:

A

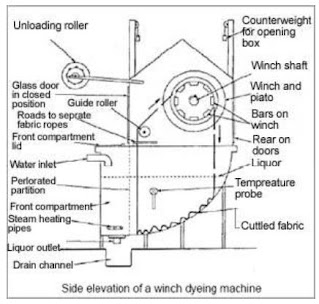

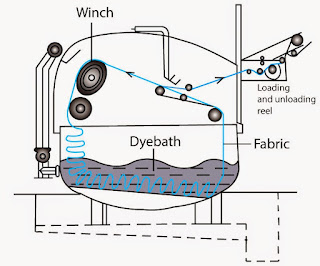

dyeing machine consisting essentially of a dye vessel fitted with a driven

winch (usually above the liquor level) which rotates and draws a length of

fabric normally joined end to end, through the liquor. Winch dyeing machines

are a low cost design that is simple to operate and maintain, yet versatile in

application proving invaluable for preparation, washing or after treatments as

well as the dyeing stage itself. In all winch dyeing machines a series of

fabric ropes of equal length are immersed in the dye bath but part of each rope

is taken over two reels or the winch itself. The rope of fabric is circulated

through the dye bath being hauled up and over the winch throughout the course

of the dyeing operation. Dyestuff and auxiliaries may be dosed manually or

automatically in accordance with the recipe method.

|

| Study Of Winch Dyeing Machine| Textile Dyeing Machineries |

Main Parts of Dyeing Machine:

- Home ship or bedroom

- Drum winch or reel

- Heat exchanger

- Buzzard

- Tank reserve

- Chemical dosing tank

- Utility lines, water line, line of immigration, steam inlet, etc.

- The controller or processor

- Weaving PLAITER

|

| Study Of Winch Dyeing Machine Textile Dyeing Machineries |

Advantages of Winch Dyeing:

Ø Construction and operation of

winch are very simple;

Ø The winch dyeing machines are

suitable for types of wet processing operations from desizing to softening;

Ø The winch dyeing machine is

suitable for practically all types of fabrics, which can withstand creasing in

rope form processing;

Ø The tension exerted on winch is

less than jigger; the material thus dyed is with fuller hand;

Ø The appearance of the dyed goods

is clean and smooth on winch dyeing machines;

Limitations of Winch Dyeing:

Ø Batch dyeing

operations needs trimming, sewing, and opening out the rope, loading and

unloading for individual lots separately;

Ø Since

several lengths of fabric are run over the winch reel into the liquor and sewn

end to end, Continuous length processing is not possible in a single batch;

Ø Fabric is

processed in rope form which may lead to crease marks, particularly in heavy, woven,

thin and light synthetics;

Ø Most of the

machine works under atmospheric conditions. More Information on Winch Dyeing.

Features and Parameters:

Ø The machine

operates at a maximum temperature 95-98°C;

Ø The liquor

ratio is generally quite high (1:20-1:40);

Ø This is a

dyeing machine for fabrics in rope form with stationary liquor and moving

material;

Ø In winch

machines, a number (1-40) of endless ropes or loops of fabrics of equal

length (about 50-100m) are loaded with much of their length immersed in folded

form inside the dye bath;

Ø As for all

forms of rope dyeing, the fabric must be fairly resistant to length ways

creasing;

Ø A perforated

separating compartment, positioned at a distance of 15-30 cm from its vertical

side creates an inter space for heating and for adding reagents;

Ø Heating can

be supplied by means of direct or indirect stem heating;

Ø The rope

passes from the dye bath over two elevated reels. The first roller is

free-running (jockey or fly roller) and the second is winch reel;

Ø The winch

reel not only controls the rate of movement of the fabric rope, but also the

configuration of the rope in the dye bath;

Ø The winch

reel does not grip the fabric positively, but by the weight of the wet fabric

and the friction between the reel and fabric;

Ø Now-a-days

stainless reels with corrugated and broken surface for increase frictional

forces are used;

Ø The maximum

motion speed of the fabric must be approximately 40m/min;

Ø The winch

dyeing method is suitable for all fabrics, expects those which tend to

originate permanent creases or which could easily distort under the winch

stretching action.

|

| Lab Winch Dyeing M/C |

Dyeing Method on Winch Dyeing Machine:

|

| Winch Dyeing Machine |

Finally,

Winch dyeing machine comes with a choice of cost-effective design low cost and simplicity of operation and maintenance characteristics after relentless when it hits versatility. From this experience, we know about the crane and the principle of its dyeing machine. They are very useful in our life mission

Related tag:

What is the working principle of winch dyeing machine?

What is a winch machine?

What is the winch speed of dyeing machine?

What is the advantage of winch machine?

winch dyeing machine pdf

winch dyeing machine price

winch dyeing process

jigger dyeing machine

Thanks for sharing, This will help for making lab reports of engineering students.

ReplyDeleteI love this article and the dyeing machine

ReplyDeleteThis is so helpful. I've got my answer.Thank you.

ReplyDelete